Vörulýsing

Laserskurðarvél úr trefjamálmi

1. Lágmark kostnaður og orkunotkunin er 0,5-1,5kw / klst. Viðskiptavinur getur skorið alls konar málmplötur með því að blása lofti;

2. Afkastamikil. Innflutti upprunalega pakkaðan trefjarlaser, með stöðugri afköst og líftími er yfir 100.000 klukkustundir;

3. Háhraði og skilvirkni, hraði skera málmplötum nálægt tugum metra;

4. Viðhald leysir ókeypis;

5. Skurðbrúnin lítur fullkomin út og útlitið er slétt og fallegt;

6. Innfluttur flutningsbúnaður og servó mótor, og mikill klippa nákvæmni;

7. Sérstakur hugbúnaður gerir kleift að hanna eða vinna grafík eða texta samstundis. Sveigjanlegur og auðveldur gangur.

Færibreyta af Laserskurðarvél úr trefjamálmi

| Laser máttur | 500W | |

| Laser uppspretta | Raycus eða IPG Laser Fiber Laser Source | |

| Laser tegund | Innfluttur trefjaleysir eða toppvörumerki Kína trefjaleysir | |

| Laser tækni | Þýskaland Tækni | |

| XYZ vinnusvæði | 2500*1300 | 3000*1500 |

| Hámark Skurðþykkt (CS) | 1mm - 5mm | |

| Hámark Skurðarhraði | 5-15 metrar / mín (allt að efni) | |

| Hámark Staðsetningarhraði | 60m / mín | |

| Laser bylgjulengd | 1070nm | |

| Lágmarks línubreidd | ≤0,1 mm | |

| Nákvæmni staðsetningar | ≤ ± 0,05 mm | |

| Endurstaðsetning nákvæmni | ± 0,02mm | |

| Hámark hreyfingarhraði | 100m / mín | |

| Stuðningur snið | PLT, DXF, BMP, AI | |

| Krafteftirspurn | 380V / 50Hz | |

| Kólna leið | Vatnskæling | |

| Vinnuborð hámark hlaða | 1000 KGS | |

| Sendingaraðferð | Ball boltaskipti | |

| Tafladrifið kerfi | Japanskt innflutt servó mótor og aksturskerfi | |

| Fókusaðferð | Eftirfarandi og Sjálfvirk Stilla fókus | |

| Stjórnunaraðferð | Hreyfingarstjórnun utan nets | |

| Stjórna hugbúnaður | Fullkominn Laser Professional skurðarhugbúnaður | |

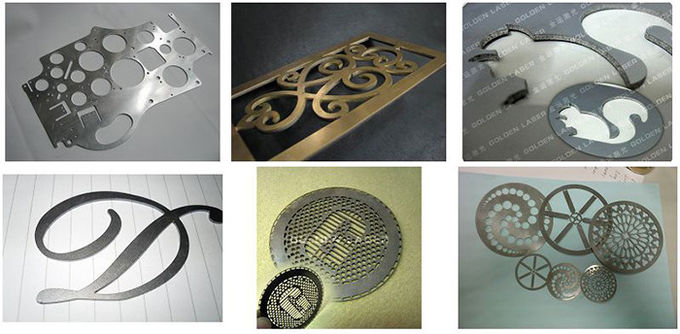

Umsókn og sýnishorn

Notað í málmvinnslu, flugi, geimflugi, rafeindatækni, rafmagnstækjum, neðanjarðarlestarhlutum, bifreiðum

vélar, nákvæmnisíhlutir, skip, málmvinnslubúnaður, lyfta, heimilistæki, gjafir og handverk,

verkfæravinnsla, skraut, auglýsingar, erlend málmvinnsla ýmis ma

Laser uppspretta valkostur

Raycus: 500W, 750W, 1000W, 1500W, 2200W, 3300W, 4400W

IPG: 500W, 700W, 1000W, 1500W, 2000W, 3000W, 4000W,

Mismunandi leysikraftur vegna mismunandi leysiskurðarþykktar, efna og framleiðslumagns.

Uppsetning

Eftir að vélin er komin á síðu kaupanda eru verkfræðingar frá seljanda ábyrgir fyrir uppsetningu vélarinnar

og gangsetning með því að nota sértækin undir aðstoð kaupanda. Kaupandi ætti að borga fyrir verkfræðinginn okkar

vegabréfsáritunargjald, flugmiða, gistingu, máltíðir o.fl.

Sameiginleg verndarþekking á leysiöryggi

Grunnreglan um leysieining og uppbygging leysiskurðarvélar

Rekstrarhæfileikar trefjaleysisskurðarvélar

Rekstur búnaðar og umsóknartilkynningin

Hæfni í daglegu viðhaldi búnaðar, aðlögun leysieininga og skipti á varahlutum.

Uppsetningar- og þjálfunartími er um 5 til 7 dagar.

Ábyrgð og þjónusta

1). 1 árs ábyrgð á allri vélinni

2). 2 ára ábyrgð á trefjaleysisgjafanum

3). Lífslangt viðhald

4). Á ábyrgðartímabilinu, ef það bilar eða sumir hlutar skemmast (nema mannlegir þættir og þættirnir

vegna force majeure), seljandi ætti að vera ábyrgur fyrir viðgerð án endurgjalds, hlutunum sem þarf að skipta um verður

útvegað frá seljanda ókeypis (Nema hraðslitahlutinn).

5). Eftir að ábyrgðartímabilið rann út þarf kaupandinn aðeins að greiða raunverulegan viðhaldskostnað.

6). Sumir viðskiptavinir, við munum fara í endurheimsókn nokkrum sinnum í eitt ár, og munum veita tæknilega aðstoð

þjónusta hvenær sem er, og útvegaðu einnig varahluti hvenær sem kaupandinn vill.

7). Viðbragðstími eftir söluþjónustu: skjót viðbrögð innan 8 vinnustunda, eftir að hafa fengið viðgerðarkallið,

Eftir sölu verkfræðingur okkar mun svara eins fljótt og auðið er.